Factors to consider when choosing a Magnetic Chuck

When choosing or using a magnetic chuck there are several key factors which must be considered which may affect the performance of the workholding capability.

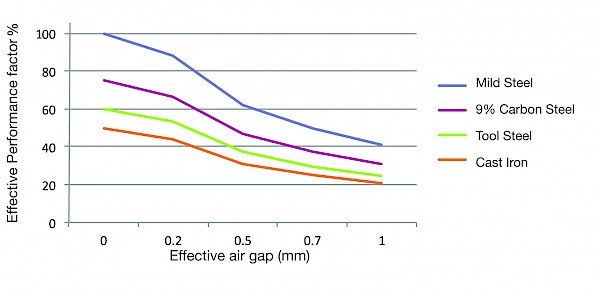

Air Gaps/Work Piece Contact

An air gap between the magnetic surface and the workpiece will reduce holding performance. The highest performance is where air gaps are kept to a minimum and the magnetic hold is maximised.

Air gaps are determined by the profile of the workpiece and the surface finish. For example a lapped fine finished product will have an micron finished even surface and have the best workholding properties, whereas a rough planed surface will have a much poorer holding force due to air gaps prevalent in the uneven surface.

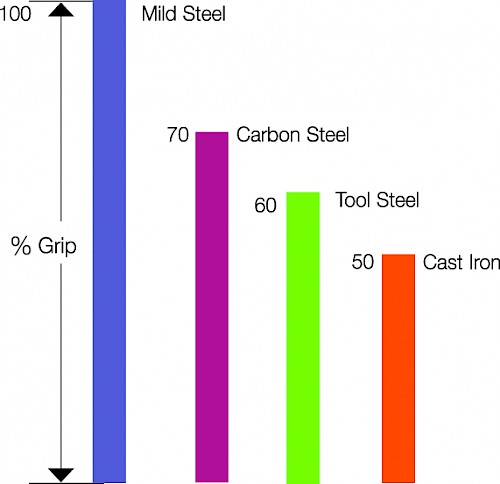

Materials Type and Configuration

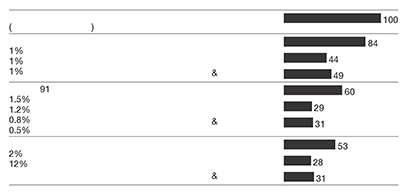

The material type determines the magnetic clamping force. Some materials have less magnetic permeability and this will affect the hold. The chart below shows some examples of how the clamping force is affected by different material types. Material, hardness, shape and flatness of the workpiece material.

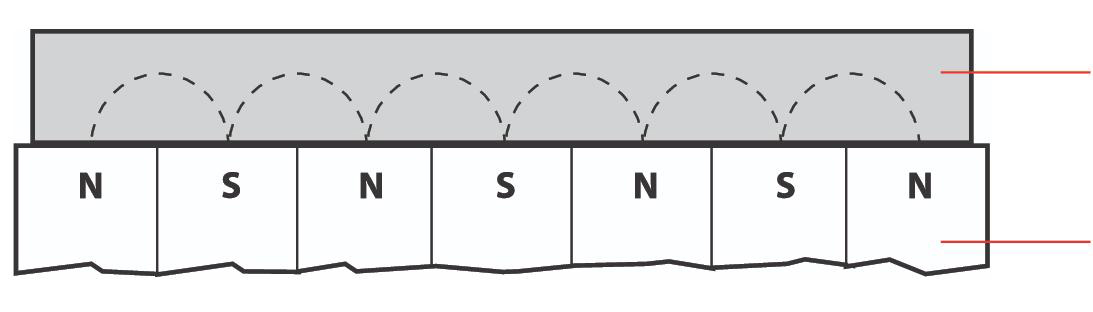

Material Thickness

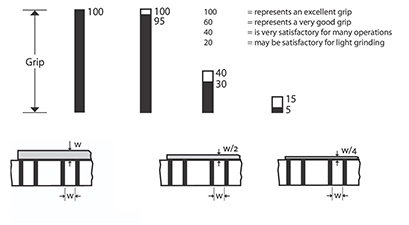

Thinner materials are less absorbent of magnetic flux. The flux path within a workpiece is a semi-circle from the centre of one chuck pole to the centre of the next. If the workpiece is thinner than this radius it cannot absorb all the flux and some passes through. The resultant pull is lower than that of a thicker workpiece when all the flux is fully absorbed. This means the hold is greater.

AX Chucks: Variation of pull with workpiece thickness:

To hold a thin workpiece securely the pole pitch and radius of the magnetic flux must be reduced. There are two main methods of achieving this.

- Fine Pole Chucks

- Induced pole Chucks - please ask for details.

These chucks are ideally suited to small thin workpieces although they can also be used to hold larger workpieces for surface grinding applications.

Condition of the Workpiece

The heat treatment of a material affects its physical structure and its ability to absorb flux. Annealed materials are best. Hardened materials do not absorb flux as easily and tend to retain some magnetism when the chuck is switched off, sometimes making it difficult to remove the workpiece from the chuck.

Residual (or retained) magnetism can be removed from a workpiece by wiping the workpiece across an De-magnetiser, once it has been removed from the chuck.

Workpiece Surface Area

Smaller surface areas have less available contact area with the magnet thereby reducing the overall holding ability. Positive or fixed stops may be required in addition on smaller workpieces.

To find out more please contact us or ead more about our workholding products